Our Services

Comprehensive Furniture Manufacturing Services in Vietnam

From CAD design and prototyping to full-scale production and quality assurance, Vietnam Maker provides end-to-end furniture manufacturing solutions from our workshop in Binh Duong, Southern Vietnam.

CAD Design & 3D Modeling

Precision Engineering for Your Furniture Vision

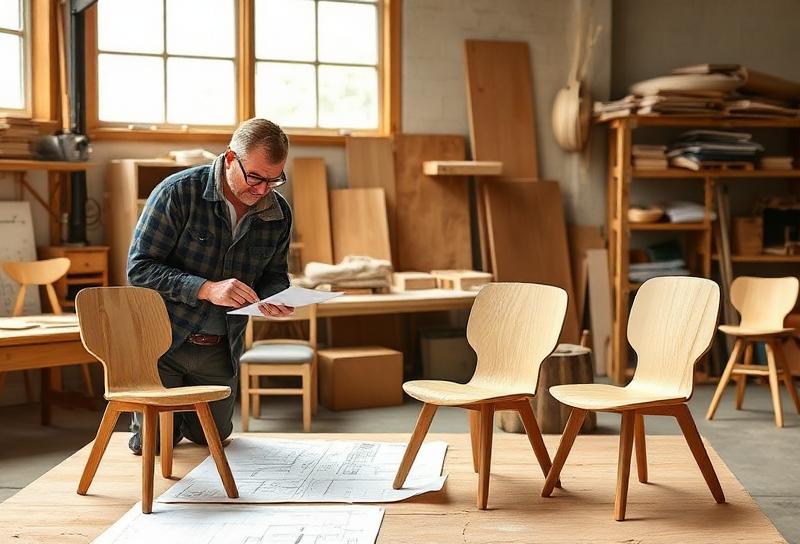

Every exceptional piece of furniture begins with a detailed design. At Vietnam Maker, our CAD design and 3D modeling service bridges the gap between your creative vision and production-ready specifications. Our experienced design team uses industry-standard software including AutoCAD, SolidWorks, and SketchUp to create comprehensive technical drawings and photorealistic 3D renders of your furniture concepts.

Whether you come to us with a rough sketch on a napkin, a reference photo from a magazine, or a fully developed concept, our designers work closely with you to refine every detail. We define precise dimensions, material specifications, joinery methods, hardware placements, and finishing details — all before a single piece of wood is cut in our Vietnam furniture workshop.

Our CAD service is particularly valuable for OEM clients who need to visualize and approve designs before committing to production. We provide multiple design iterations, allowing you to experiment with different proportions, materials, and styles until the design is perfect. This attention to detail in the design phase saves time, reduces waste, and ensures that the final product from our furniture factory in Vietnam matches your exact expectations.

Sampling & Prototype Development

Touch, Feel, and Approve Before Production

Sampling is a critical step in the furniture manufacturing process, and at Vietnam Maker, we treat it with the importance it deserves. Our sampling and prototype development service allows you to physically evaluate a piece of furniture before committing to a full production run. This hands-on approach minimizes risk, ensures satisfaction, and builds confidence in the partnership between you and our Vietnam furniture factory.

Our skilled craftsmen build each prototype with the same care and precision as a final production piece. Using the specified materials, joinery techniques, and finishes, we create samples that accurately represent what the finished product will look and feel like. Typical turnaround for a first sample is 2-4 weeks, depending on complexity — fast enough to keep your product development timeline on track.

We encourage iterative sampling. After reviewing the initial prototype, you can request adjustments to dimensions, material choices, finish colors, or structural details. Our team documents all changes meticulously, ensuring that approved samples become the benchmark for consistent quality throughout the production run. This iterative process is what makes Vietnam Maker a trusted furniture maker in Vietnam for brands that demand perfection.

Indoor Furniture Production

Full-Scale OEM Manufacturing with Artisan Quality

At the heart of Vietnam Maker's offering is our full-scale indoor furniture production capability. Our Binh Duong-based furniture factory combines the efficiency of modern manufacturing equipment with the irreplaceable touch of skilled artisans. This hybrid approach allows us to produce consistent, high-quality furniture at competitive prices while maintaining the handcrafted character that sets Vietnamese-made furniture apart.

We specialize in a wide range of indoor furniture categories: dining tables and chairs, coffee tables, sideboards and buffets, bedroom furniture, home office desks and shelving, living room furniture, and custom decorative pieces. Our production capacity accommodates both small custom orders and large OEM production runs, making us an ideal partner for boutique brands and established furniture companies alike.

Our production workflow is optimized for quality at every stage. Raw materials are carefully selected and acclimatized. CNC machinery handles precision cutting and shaping. Skilled artisans perform hand-finishing, assembly, and detail work. And our quality control team inspects every piece before it's cleared for packing. This is the standard at our Vietnam furniture workshop — where tradition meets modern manufacturing excellence.

Quality Control & Inspection

Rigorous Standards for Every Furniture Piece

Quality is not just a department at Vietnam Maker — it's a philosophy embedded in every step of our manufacturing process. Our quality control and inspection service ensures that every piece of furniture leaving our Vietnam furniture factory meets the highest international standards for craftsmanship, durability, and aesthetic excellence.

We implement a multi-stage quality control process: incoming material inspection verifies that all wood, hardware, and finishing materials meet specifications. In-process checks during production catch any issues early. And final inspection before packing evaluates surface finish, structural integrity, dimensional accuracy, hardware function, and overall appearance. We use calibrated measuring tools, moisture meters, and finish thickness gauges to ensure objective, consistent quality assessments.

For OEM clients, we offer customized QC protocols tailored to your brand's specific standards. Our QC team can work from your inspection checklists, or we can help you develop appropriate quality benchmarks. Detailed inspection reports with photographs are available upon request, giving you full visibility into the quality of every shipment from our furniture factory in Vietnam.

OEM/ODM Manufacturing Services

Your Brand, Our Expertise — Custom Furniture Made in Vietnam

Vietnam Maker offers comprehensive OEM and ODM manufacturing services for furniture brands, retailers, interior designers, and hospitality companies worldwide. As an experienced furniture maker in Vietnam, we understand the unique requirements of white-label and custom manufacturing partnerships — from protecting your intellectual property to meeting strict delivery schedules.

Our OEM service allows you to leverage our manufacturing expertise while selling under your own brand. You provide the designs, specifications, and branding requirements, and we handle everything from material sourcing and production to quality control and export-ready packaging. With low minimum order quantities and flexible production scheduling, we make it easy for brands of all sizes to manufacture furniture in Vietnam.

For ODM partnerships, our design team collaborates with you to develop original furniture designs based on market trends, your brand identity, and target price points. We handle the entire product development cycle — from concept sketches and CAD modeling to prototyping and production. This service is ideal for companies looking to expand their product range without investing in an in-house design team. Partner with our Vietnam furniture workshop to bring fresh, market-ready furniture designs to life.

Ready to Discuss Your Furniture Project?

Contact Vietnam Maker today for a free consultation. Our team is ready to help you bring your furniture vision to life in our Binh Duong workshop.

Get a Free Quote